November 30th, 2022 - Prepping the ViS JDM Techno R / Mugen PRO.2 replica bumper

Back in August, with summer temps back in full swing I set upon further tweaking the ViS/Mugen replica.

I started by trimming a little bit off the inside wheel arch to clear the inner fender liner a little better. It seemed to be a little bit too tight during last years test-fit. I didn't take much off, maybe 1mm. Just enough to make it a wee bit easier to slide over the liners.

Since I already know I'll be having a body shop sand and widening the holes for the signal lights, I set upon wedging them in temporarily and marking and drilling out the screw holes. The fibreglass was a little too wide for the u-nut, so I had to sand it down a little. During my first test-fit mounting the signal light, I accidentally broke the mount point, and then following up that stellar performance with a repear for the other side. Lesson learned. The holes for the signal light screw need to be larger to accommodate some movement of the u-nut.

I found a Honda OEM part number for some License Plate mount u-nuts that should work well to replace the existing, rusty u-nuts.

I wasn't happy with the fitment of the previous test mounting so I thought I'd try another test-fit at some point in the summer, after making some more tweaks to the mounting holes and mounts etc.

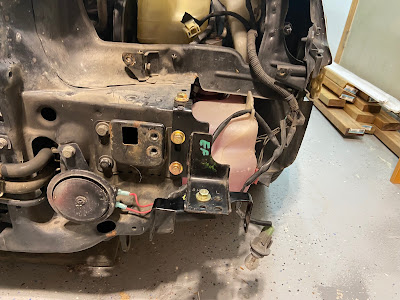

I decided to try flipping the mounts 'upside down' to see if the holes line up any better, and I chose to try the genuine Mugen mounts since they were bent a little wider than 90° and I wanted to see if bending my replica mounts could eliminate the need for spacers, or at minimum reduce the need for as large a spacer.

.JPEG) |

| After installing the mounting bracket the opposite way, the holes line up perfectly now |

.JPEG) |

| After installing the mounting bracket the opposite way, the holes line up perfectly now |

|

| Originally had these on upside down and the holes didn't line up very well as you can see |

|

| Originally had these on upside down and the holes didn't line up very well as you can see |

Before test-fitting the bumper, I wanted to test-fit the signal covers with the signals "installed". The holes don't line up between the two covers (smoked and clear), so I'll likely only be able to install one set and I wanted to get a feel for which one I liked better, as well as ensuring the clearance is good between the cover and the actual indicator.

I'm leaning heavily to the clear signal light covers for a couple reasons, the main one being that I don't need to attract any unwanted attention from the police. My car is already a heat-score being that it's right-hand-drive and the government here is always talking about banning them or limiting them in some way, so the less attention I attract, the better. The second reason is that I don't really have heavily smoked corner or side markers installed so I thought it may look a little more odd than it already does with the Password:JDM smoked amber corners and sides with the OEM amber indicators. It's also a similar reason why I never jumped at those clear signal lenses being sold on eBay.

Never one to miss an opportunity, I lined up the tilt bracket for the license plate frame so I could mark the spot where I need to drill a hole to allow the electrical wires to pass through for the jiko shiki (illuminating) plate.

Everything went pretty well until the actual drilling of the hole. I tried everything. Running the bit slowly so as not to heat up the metal, I tried different bits, I tried hammering a nail in the center so I could get a drill but to bite into something, but nothing worked. Sadly, the stainless steel was just far too strong for me to drill through.

After completing the signal light fitment test and the tilt bracket markup, I did another test-fit of the bumper with the bent Mugen brackets (installed the opposite way I had them in 2021) and it fit was MUCH better. So much so, that even though the fitment wasn't 100% perfect, I felt it was good enough to leave on the car for the remainder of the season. Even unpainted and not lined up perfectly, it made the car look much more "complete" with the last piece of the PRO.2 kit installed.

As a matter of fact, I liked it so much, that I decided that very same weekend that I was not only going to leave the bumper on for the rest of the season, I was also going move heaven and earth to get the car into the body shop this off-season to get it painted and installed properly.

Before the end of the season, I went out to Triple K Autobody just outside of Calgary to speak to the owner, Stu, about getting an estimate. I've heard from a couple people locally that he used to race CRXs and still has one or two in his personal collection. I couldn't think of a better place to entrust to my baby than someone who knows and understands the love and the passion. I certainly didn't want to take her to any ol' body shop who thinks that fixing up an old "rice rocket" is a waste of their time.

After receiving the estimate, I started working straight away on getting the preliminary work I needed to do in order to get her in to Triple K. One of the things I wanted to do was source a different tilt frame bracket, one that might be a little easier to drill through. While hunting for a replacement tilt bracket, I came across a tilt bracket, in black aluminum, with a design that doesn't show a gap between the two brackets, something I really liked the sound of!

Repeating the same process as with the stainless steel bracket, I mounted, levelled and marked the bracket, and was able to drill through the metal quite easily. I sanded the edges of the hole until smooth and re-installed the bracket to test it out. Perfect fit, and the harness for the license plate slid right through with no issues.

Next up, was taking the headlights off for restoration. If interested, I have another post about that process in this blog, so I won't get into it much here. While the headlights were off getting shined up, I didn't want the bumper to be damaged so I reattached it to the car, and much to my surprise, it fit much better without the headlights installed. The holes on the 3 tabs line up almost perfectly to the bolt holes on the slam panel (T-Bar). I'd drilled the holes on the tabs corresponding to the marks from mold of the original Mugen bumper, and was disappointed when they didn't line up very well in my previous test-fits. Stu at the body shop even talked to me about the possibility of removing them altogether, which I wasn't a fan of. I'll definitely be passing this news on to the Triple K so that we can keep those tabs intact during installation.

.JPEG) |

| Without headlights, the holes in the tabs line up with the T-Bar much better |

.JPEG) |

| Without headlights, the holes in the tabs line up with the T-Bar much better |

.JPEG) |

| Without headlights, the holes in the tabs line up with the T-Bar much better |

.JPEG) |

| Without headlights, the holes in the tabs line up with the T-Bar much better |

|

| With the headlights installed, the holes didn't quite line up |

|

| With the headlights installed, the holes didn't quite line up |

The final step prior to taking the car into the body shop was to work on the fitment of the fog lights. 'll be doing another post on the fog light installation in greater detail in an upcoming post.

Despite confirming I have the OEM brackets, and the OEM light housings (stamped L & R as well as SH2), I found that the reinstallation of the bumper with the brackets installed was much more difficult and made lining everything up much more challenging. I have a feeling it has more to do with the having everything not quite lined up. I have pictures saved in my CRX folder showing two fog light installations on CRXs that I know for certain used the ViS replica, so I know that they will fit. Folks I've spoken to online were quite confident no large modifications are needed to the bumper to get the fog lights fitted to the car. For what that's worth... Though the photos I have would tend to agree with them.

|

| Left bracket |

|

| Right bracket |

.JPEG) |

| Levelling up |

So as of now, I'm just waiting for the body shop to bring out their covered trailer to pick up the CR-X. His shop has been quite busy with collision repairs and the pick up is also weather-permitting, so it's been a challenge to coordinate but the car is ready, the money is ready and the shop has agreed to do the work. I'll post updates as I receive them!

Remember, this blog was written in chronological order so, you will need to click OLDER POSTS to move forward in time, and click NEWER POSTS to go backwards.

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.JPEG)

.jpeg)

.JPEG)

.JPG)

No comments:

Post a Comment